1.Raw Material Selection

2.Saw Cutting

3.Forming

The two openings of the shell are heated up to as high as 1250°C, and then they are processed into closed shape with the help of CNC hot spinning lathe. The hot spinning lathe is characterized by fast processing speed with excellent precision and high pass rate, thus greatly improving production capacity and product quality.

4.Spherical Grinding

5.Heat Treatment

The high temperature electric-heating furnace is a very important equipment during the process of manufacturing accumulator shell. The accumulator shell is placed inside this equipment to be heated up to 900°C, and its mechanical properties, especially the impact resistance, stretch-ability and hardness will be enhanced to a large extent after quenching and tempering, so that the accumulator will work more safe and more reliable.

6.Mechanical Property Tests

The tests includes tensile test,yield strength test,elongation test,flattening test and hardness test, all these tests will be done to check if the mechanical property of accumulator shell is up to the design requirements.

7.Sandblasting

8.Machining

Machining is of great significance for the entire production flow because the gas port and the fluid port of the accumulator are both fabricated during this process. An automatic CNC lathe is responsible for this step, and it shows some outstanding features,such as, it realizes multi-coordinate simultaneous motion control which makes it be able to process complex-shaped components and the processing error is very small. For some different sizes of components, the operator just needs to change the CNC program, so as to save a lot of preparation time. Moreover, this lathe shows good precision and high rigidity, and its productivity is 3-5 times after comparing with common types.

9.Magnetic Particle Inspection

10.Dimension and Appearance Inspection

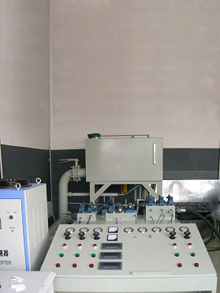

11.Hydraulic Test

The hydraulic test is the last but the most important production test when manufacturing accumulators. A pressurization device is used to increase the hydraulic pressure inside the shell to 1.5-2 times of design valve to check if leakage occurs under this high pressure, whether the gas port and fluid port are well sealed, etc. After shells pass this test, they could be used to assemble accumulators.

12.Stamping

13.Phosphating

14.Painting